As the complexity of machines used in CNC machine shops increases, so does the importance of ongoing preventative maintenance. The machines we use, like our 5-axis machine center, produce complicated and precise parts, which calls for specially designed hardware and software. Every element of our equipment, from the coolant to the spindles to the chips, must function properly to produce the elaborate components our customers need. We often work on tight timetables to deliver parts for our customers, and it is critical to keep our advanced technology in top shape to avoid any possibility of downtime.

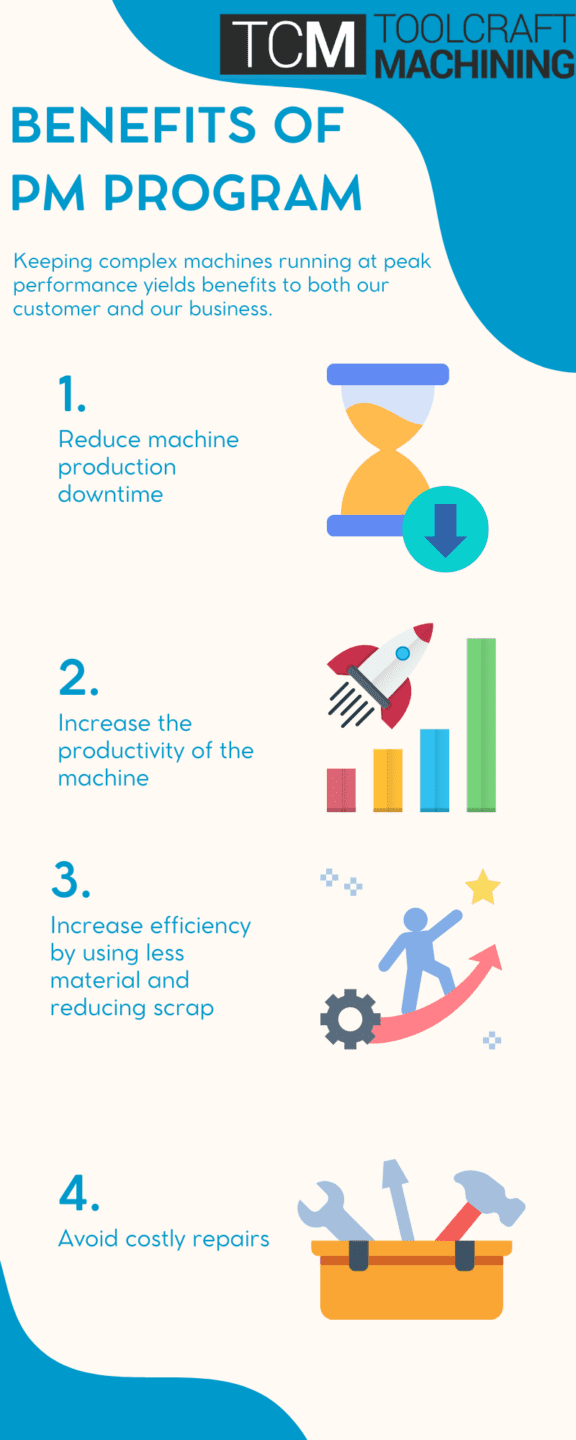

Here are a few reasons why Toolcraft Machining emphasizes (through training and accountability) proper maintenance programs for each of our machines.

To learn more about the timetable and the tasks that fall under preventative maintenance, see the article and checklist provided by Shibaura: Read Article >>

Given the rigor with which we maintain our complex CNC machining equipment, you can have confidence in our ability to produce the complicated and precise parts you need.

Contact us today for more information on our capabilities, certifications and the industries we serve. You can view our complete equipment list here.

RECENT POSTS

- A Step Above: Toolcraft’s Machining Experts Score CMMC Compliance

- The Halfway Point – Toolcraft Continues To Combat The Industrial Manufacturing Labor Shortage

- Manufacturing Safety: How Toolcraft’s Commitment Nurtures Employee Culture

- Tighter Tolerances, Increased Security, and Strict Quality Standards: Why Toolcraft is Your Ideal Partner for Aerospace CNC Machining

- How 5 Axis Machining Improves Your Projects