In our industry, some complex materials have a reputation for being difficult to work with. These materials include titanium, a go-to material for the defense and aerospace industries, as well as nickel alloys like Inconel.

So, what makes a material challenging? In some cases, obtaining the material can be the issue, but often it is the properties of the material itself that create challenges.

Toolcraft’s 60 + years of experience and advanced technology, such as our 5-axis machine or the DMG MORI NLX 6000, give us the ability to work with many difficult-to-machine materials that other CNC machining facilities are not able to handle.

Inconel, Ni-hard, and titanium are among the many types of complex materials that we work with on a regular basis. View our materials list to learn about some of the common quote requests we receive for each type of material. Keep in mind that we also regularly quote variations of all material types.

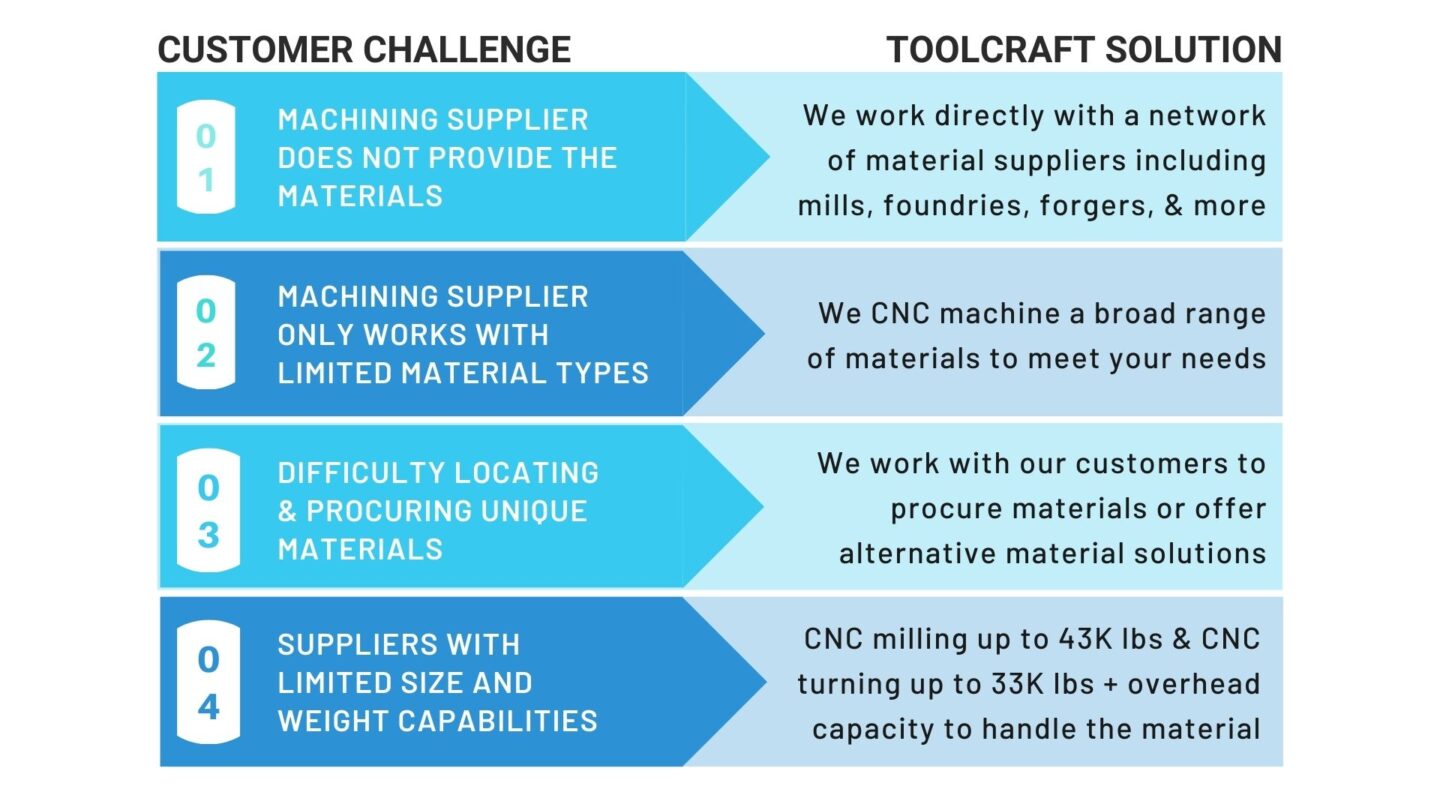

Below are some of the complex material challenges we solve for our customers:

Toolcraft Machining provides solutions for our customer’s most complex material problems. Get in touch today to learn how we can solve your material challenges!

The best place to start is by completing a request a quote form here.

RECENT POSTS

- A Step Above: Toolcraft’s Machining Experts Score CMMC Compliance

- The Halfway Point – Toolcraft Continues To Combat The Industrial Manufacturing Labor Shortage

- Manufacturing Safety: How Toolcraft’s Commitment Nurtures Employee Culture

- Tighter Tolerances, Increased Security, and Strict Quality Standards: Why Toolcraft is Your Ideal Partner for Aerospace CNC Machining

- How 5 Axis Machining Improves Your Projects