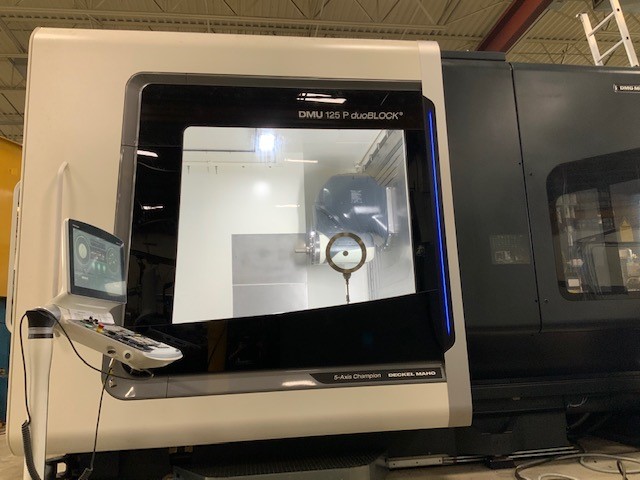

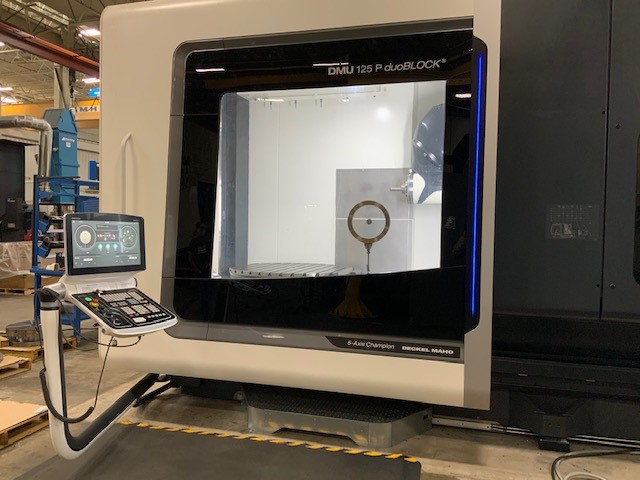

Since expanding our machining capabilities with the addition of the DMG MORI DMU 125 P duoBLOCK 5-Axis machine in 2020, we’ve experienced firsthand the benefits of 5-axis machining. But first, what is 5-axis machining? It refers to the ability to move a tool or part in five different axes simultaneously. So, in addition to the usual three primary axes (X,Y,Z) of basic machining, a 5-axis machine can rotate two additional axes (A & B) for a multidirectional approach. Some of the benefits we’ve seen include increased productivity and higher accuracy with lower overall costs.

Extreme Precision & Increased Accuracy

With the HSK-A100 tool connection and 63 available tool pockets, the DMU 125 P has the capability to run parts quickly, accurately, and efficiently. The duoBLOCK system with optimized component structure, large drive system, and three-point support within the machine create rigidity throughout the machine. This increases the accuracy of machining parts.

The technology within the DMU 125 P is advanced in many ways. The 3D quickSET is a tool kit for checking and improving accuracy of all five axes. The CNC measures spindle displacement and corrects errors automatically.

Faster Turnaround with Increased Efficiency

Another feature, the Renishaw Probe Sensor, allows the measurement of features while the part is inside the machine. It has the capability to measure hard-to-reach areas, allowing for easy and accurate inspection. The sensor automatically calibrates itself, which allows our team to inspect parts quickly and at a lower cost, which results in faster turnaround for our customers.

Machining Unique/Complex Parts & Angles

A key aspect of the DMU 125 P is its ability to perform interpolation turning. This machining process takes place in a circular movement around and inside the workpiece, with the spindle perpendicular to the direction of movement. This feature allows us to turn external features on parts. Interpolation turning can create symmetrical features on non-symmetrical components, allowing the creation of unique parts and features.

Single Set Up

Machining a contoured part on a 3-axis machine calls for multiple setups and manual rotating. The 5-axis machine gives us the potential to manufacture parts a single set up–saving time and minimizing errors that generally accompany multiple set ups.

Better Surface Finishes

The fourth and fifth axes allows the part to be oriented so that it is closer to the cutting tool. This allows us to use a shorter cutting tool. This minimizes vibration at high cutting speeds to achieve a better surface finish.

If you would like to reap some of the benefits of 5-axis machining, get started by requesting a quote or contacting us here: https://toolcraft.com/contact-us/.

RECENT POSTS

- A Step Above: Toolcraft’s Machining Experts Score CMMC Compliance

- The Halfway Point – Toolcraft Continues To Combat The Industrial Manufacturing Labor Shortage

- Manufacturing Safety: How Toolcraft’s Commitment Nurtures Employee Culture

- Tighter Tolerances, Increased Security, and Strict Quality Standards: Why Toolcraft is Your Ideal Partner for Aerospace CNC Machining

- How 5 Axis Machining Improves Your Projects